Conservation of wet crushed cereal grain

Crimping is the method of processing and conservation of corn harvested 3-4 weeks before common harvest maturity, mainly by means of chemical preservatives. This involves also using of the crushing machine specially modified for crushing of wet seeds. As early as in the beginning of the last century it was found that grain of cereals reaches its maturity and the highest nutrient content at decrease in moisture to 35 %. At common harvest the harvesters wait therefore for the moment when the moisture values are even lower but the nutrient content in seeds changes no longer. The moisture of seeds is then adjusted by drying to optimal value for storage. However, there is an alternative for fodder purposes – to harvest the grain when it reaches the maximum nutrient content, then to crush and to conserve it. The fodder is not dried but is stored with the original water content. Grain fodders can be then conserved in two ways. The first is the decrease in the osmotic pressure in cells – drying (drying plants, active aeration, etc.). In this conservation method, losses of nutrients are the lowest but the most expensive method is concerned. The second possible way is the conservation of wet grains. Thanks present state-of-the-art knowledge this technology reached significantly higher level. Main advantages of this method include the possibility to store the own production of fodder cereals in the own plant, without using of processing fattening facilities. Further advantage is mitigation of risk of unfavorable weather at the harvest, reduction of harvest losses, the grain quality enhancement and its usability (digestibility), prevention of germination of grains and also activation of enzymes after chemical treatment and acidification of the fodder. This method was originally invented in Finland and at present this is relatively widely used in many countries of Europe and other parts of the world. Mechanical method of treatment of wet grains is thus concerned. Principle of this technology consists in the grain crushing at its moisture from 32 to 40 %, which are optimal values and should be observed in practice. The reason is simple. After chemical treatment it is necessary to use the preservative. At decrease in moisture the preservative consumption rises, which is used in the optimal case from three to six liters per 1 t of material. Even the material with lower moisture can be crushed and preserved indeed because the water content in grain can be various in the different fields and in a sunny day the evaporation can cause rapid loss of moisture up by 10 %. However, in such a case it is desirable to add water to processed corn. Significant advantage of this system is then a possibility to harvest cereals 3-4 weeks before the usual date, thereby to distribute harvesting.

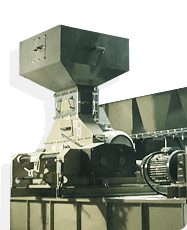

Elimination of costs on cleaning, drying and storage is also not negligible. The advantage is also the fact that crop treated in this way does not raise dust thereby the risk of development of respiratory diseases and other health problems of animals and people is avoided. Handling of material is also cheaper because it includes lower number of working operations than handling of dry fodder. Production parameters are the same as at dry corn. Important rule is to harvest grain with the moisture from 32 to 40 %. Whereas wet grain cannot be crushed by means of classical machines, it is necessary to use special machines. The preservative is added to crushed material directly in the machine by means of the dosing device. Proper thinning of the preservative in the ensiled material, eventually its spraying by nozzles, are also important. Output capacity of the wet grain crushers ranges according to used type from 15 to 80 t/ hour. Main working elements of machines are crushing rollers, which are fluted. Not only common cereals but also maize, pea, bean, lupine and others can be crushed. Apparent advantage of the ROmiLL machines is the fact that working rollers need not be replaced at change of crushed raw products. Further technological principle is the necessity to process grain within 24 hours after harvest. The material treated in this way can be stored in common silage constructions (troughs) where the surface is to be covered by foil and subsequently loaded or in silage bags. At harvesting of wet grain by means of the harvester thresher, especially the travelling speed is to be adhered – to drive with reduced speed due to larger volume of grain. It is possible to feed the fodder conserved in this way earliest after 2-3 weeks. This is intended both for cattle and pigs. Certain disadvantage is lower content of vitamin E, which is to be added subsequently to feed ration. In order to achieve the whole successful process of the wet grain conservation, several main requirements are to be met: · to use the well-designed storage construction or high-quality silage bags, · to harvest crops by three weeks ahead of the common harvest and to assure that all grains will be crushed, · to apply uniformly the proper quantity of the preservative, · to silage the grain at moisture 32-40 % and within 24 hours after harvesting, · to load the surface of stored material (200 kg/m2) when the moisture of the ensiled material is about 40 %, eventually to press properly the grain into the silage bag at perfect displacement of air, · to plan so that approximately 4 – 5 cm per day of front wall from the silo pit, eventually about 30-50 cm per day from the silage bag, will be consumed.

Read on

All articles

Miniature industrial feed mill in Mitrov, Czech (2t/hr)

Miniature industrial feed mill in Mitrov, Czech (2t/hr)

Budissa Days 2025

Budissa Days 2025Are you interested in our products or do you need more information?

Contact