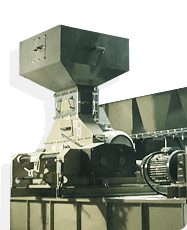

ROmiLL Grinders and ROmiLL crimpers

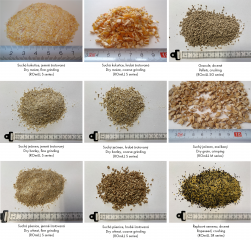

The difference between stationary machines for processing of dry grain - grinders (ROmiLL S series) and crimpers (ROmiLL M series).

ROmiLL S series

- grinder

- sharp rollers

- rotations of rollers 2:1 (1 000 : 500)

- the grain is cut

During roller grinding, grain is processed by shearing when passing through the grinding area between two grooved rollers that rotate at different speeds. Grindings from roller grinders feature their homogenous structure with a minimum dust content. After a consultation with us, it is possible to choose from several grooving types and also from two surface finishes of working rollers.

ROmiLL M series

- the rollers are not sharp

- rotations of rollers 1:1 (370 : 370)

- the grain is pressed

The roller crimpers treat grain by the action of the pressure between two rollers that rotate at the same circumferential speed. The purpose of processing feed by crimping is to transform a caryopsis into a cohesive flake. Its integrity is significantly influenced by the moisture of the raw material to be processed. After a consultation with us, it is possible to choose from two surface finishes of working rollers. Crimped feed is intended for ruminants.

Read on

All articles

Budissa Days 2025

Budissa Days 2025

Storage hoppers LODA for a customer from the Czech Republic

Storage hoppers LODA for a customer from the Czech RepublicAre you interested in our products or do you need more information?

Contact